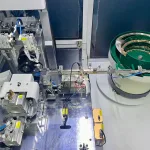

Torsion Spring Full-Automatic Assembly Machine

High-speed automated system for precise torsion spring feeding, positioning, insertion, pressing, and inspection.

The machine enables stable and synchronized torsion spring feeding and automatic insertion, with high-precision assembly tooling and real-time quality monitoring. It significantly improves production efficiency and consistency while reducing manual labor intensity.

| Cycle Period | 3 S/PCS |

| Number of Assmbled Materials | 1 |

| Equipment Utilization Rate | 95% |

| First Pass Yield | 99.50% |

| Required Operators | 0.5 |

| Dimensions | L1600mm*W900mm*H900mm |

| Power | 1 KW/H |

| Operating Air Pressure | 0.5-0.7MPa |

This machine is a fully automatic integrated unit that performs feeding, reed angle twisting, assembly, riveting, inspection, and unloading. It achieves fully automated product production through an intelligent control system, a CCD vision system, and an integrated application system; simple operation is realized via a human-machine interface, featuring strong functionality, wide compatibility, and a high product first-pass yield.

Applications:

EV Charging Connector Springs

Automotive Connector Locking Springs

Industrial Mechanism Spring Parts

UAV / Model Connector Components

- Equipment installation and commissioning: Provide professional technicians for on-site installation and commissioning to ensure normal operation.

- Training service: Provide comprehensive technical training for customer operators and maintenance personnel to ensure proficient operation.

- Warranty service: 1-year warranty for the whole machine, 2-year warranty for core components, and lifetime technical support.

- Maintenance service: Response within 2 hours after receiving fault notification, and arrange technicians to arrive within 48 hours (domestic).

- Parts supply: Long-term supply of original genuine parts to ensure continuous and stable operation of the equipment.