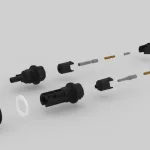

PV Connector Automatic Assembly Machine

High-speed automated assembly solution for photovoltaic connector terminals, housings, seals, and locking components, supporting full-process precision positioning and inspection.

The system adopts high-precision visual guidance (such as CCD positioning) to solve the alignment difficulties of micro-components. The machine performs automatic feeding, insertion, locking, sealing, torque control, and final inspection. Defective parts are automatically rejected, ensuring consistent product quality and stable production output.

| Cycle Period | 3S/PCS |

| Number of Assmbled Materials | 5 |

| Equipment Utilization Rate | 90% |

| First Pass Yield | 99.5% |

| Required Operators | 0.5 |

| Dimensions | L4000mm*W1200mm*H1900mm |

| Power | 3KW/H |

| Operating Air Pressure | 0.5-0.7MPa |

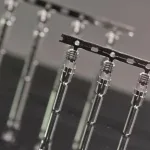

- MC4 Series Automated Mass Production

- The equipment supports quick mold changeover, enabling it to adapt to the production of connectors of different specifications (such as MC4, H4, etc.).

- The vision system identifies scratches, material shortages, and stains, and defective products are automatically rejected by the air-blowing device.

- Process Content:

- Metal wires (copper/tinned copper) and plastic pellets (nylon, PBT, etc.) are automatically fed via vibratory feeders and conveyors.

- A vision system is used to identify the orientation of materials, and a deviation correction device ensures precise positioning, avoiding errors caused by manual intervention; meanwhile, it is equipped with an automatic insertion and extraction force testing device.

- Core Steps:

- Terminal Insertion: A robotic arm accurately inserts metal terminals into plastic housings, and force feedback ensures that the insertion is in place.

- Locking Mechanism Installation: Accessories such as springs and buckles are supplied by vibratory feeders, and the assembly is completed by robots.

- Difficulty Breakthrough: High-precision vision guidance (e.g., CCD positioning) is adopted to solve the alignment problem of micro-components; the vision system identifies scratches, material shortages, and stains, and defective products are automatically rejected by the air-blowing device.

Applications: PV Connector Production Lines (e.g., MC4)\ Solar Power System Wiring Harness Manufacturing\ New Energy Storage and Photovoltaic Equipment Plants\ Industrial Outdoor Waterproof Connector Manufacturers

- Equipment installation and commissioning: Provide professional technicians for on-site installation and commissioning to ensure normal operation.

- Training service: Provide comprehensive technical training for customer operators and maintenance personnel to ensure proficient operation.

- Warranty service: 1-year warranty for the whole machine, 2-year warranty for core components, and lifetime technical support.

- Maintenance service: Response within 2 hours after receiving fault notification, and arrange technicians to arrive within 48 hours (domestic).

- Parts supply: Long-term supply of original genuine parts to ensure continuous and stable operation of the equipment.