The advantages of pneumatic execution in automated machines application

Table of Contents

Today, companies are increasingly importing automated machines to optimize operations, increase productivity, and stay competitive in their markets—especially in industries like connector manufacturing that rely on high-efficiency assembly equipment. And Pneumatic execution is crucial in automated machines, as it directly affects the stability and efficiency of connector assembly machines and other industrial automation equipment. In this article, we will discuss some of the advantages of pneumatic execution in automated machine applications.

What is the pneumatic execution in the automation industry?

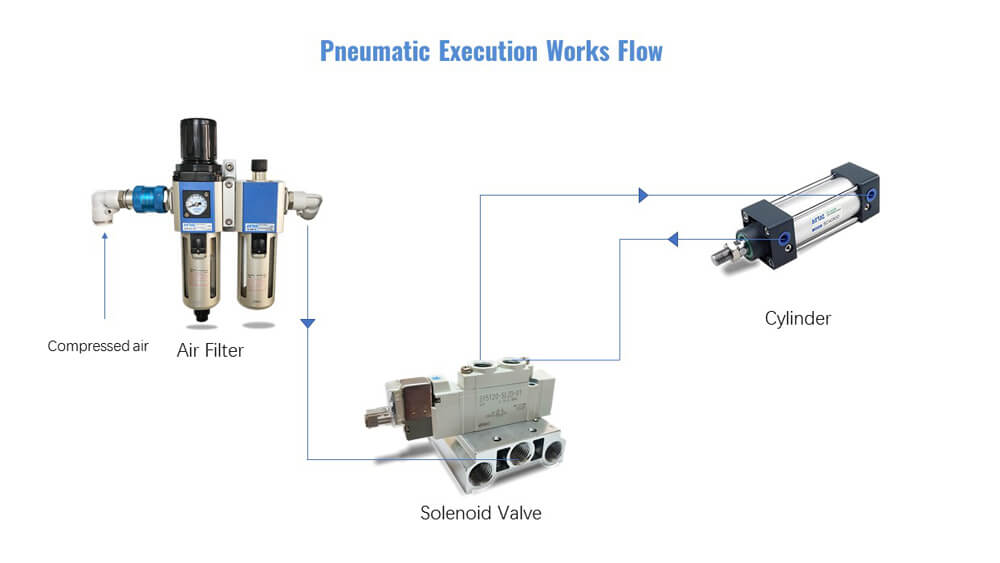

Pneumatic execution is a type of automation technology that utilizes compressed air to power components like compressor air filters, solenoid valves, and cylinders—key parts for controlling the movement and behavior of machinery in various industrial applications, including connector assembly and automated assembling machines. This technology is widely used in automated equipment due to its reliable performance.

How the pneumatic execution works?

Pneumatic execution works by utilizing compressed air, which is stored in a tank or compressor, to create force that is then transferred to a mechanical system through air filters, solenoid valves, and cylinders—core components that ensure smooth operation of automated machines. The pressure of the air causes the cylinder to move, performing the intended mechanical action (such as pressing or positioning in connector assembly machines).

High efficiency of pneumatic execution

Pneumatic systems are highly efficient when it comes to energy consumption—an important advantage for automated machines that run continuously. They can produce high forces and speeds with minimal energy input, which makes them ideal for use in high-speed automated machines like connector assembly equipment. Pneumatic systems are also highly responsive, which means that they can quickly respond to changes in the input signals—critical for ensuring precision in connector assembly. This high efficiency and responsiveness make pneumatic systems ideal for use in automated machines that require high levels of precision and accuracy.

Low Maintenance of pneumatic execution

Another advantage of pneumatic execution in automated machine applications is that it requires very little maintenance—reducing downtime for connector assembly machines and other industrial automation equipment. Unlike hydraulic systems, pneumatic systems do not require any hydraulic fluid, which means that there is no risk of leaks or contamination (a major concern for connector production, where cleanliness affects quality). Pneumatic systems also have fewer moving parts, which reduces the chances of wear and tear. This low maintenance requirement makes pneumatic systems ideal for use in automated machines that operate in harsh environments or that require continuous operation (e.g., 24/7 connector assembly lines).

Cost-Effective of pneumatic execution

Pneumatic systems are generally more cost-effective than hydraulic or electric systems—an important factor for businesses investing in automated equipment. The cost of pneumatic components such as air filters, solenoid valves, and cylinders is relatively low, which makes them ideal for use in large-scale automated machines like high-volume connector assembly machines. Pneumatic systems also require less infrastructure than hydraulic or electric systems, which reduces the overall cost of installation for automation projects. Additionally, pneumatic systems are easy to install, which means that automated machines can be up and running quickly—shortening the time to start connector production.

Safe Operation of pneumatic execution

Pneumatic systems are generally considered safe to operate—protecting workers and automated machines in connector manufacturing workshops. They do not use any hazardous liquids or chemicals, which reduces the risk of spills or leaks (avoiding damage to connector components). Pneumatic systems also do not produce any sparks, which reduces the risk of fire or explosion (critical for workshops with flammable materials near assembly equipment). Additionally, pneumatic systems are relatively quiet, which makes them ideal for use in environments where noise levels need to be minimized (improving working conditions around automated machines.

Versatility of pneumatic execution

Pneumatic systems are highly versatile and can be used in a wide range of applications—adapting to different types of automated machines. They can produce high forces and speeds, which makes them ideal for use in heavy-duty applications such as material handling in connector assembly lines. Pneumatic systems can also be used in more delicate applications such as pin inserting or packaging in connector assembly machines. This versatility makes pneumatic systems ideal for use in a wide range of automated machines, from small-scale assembling machines to large-scale automation equipment.

In conclusion, pneumatic execution offers several advantages that make it an ideal technology for use in automated machine applications—especially for connector assembly equipment and other industrial automation systems. Pneumatic systems are highly efficient, low-maintenance, cost-effective, safe, and versatile. These advantages make pneumatic systems ideal for use in a wide range of applications, from connector assembly to heavy-duty material handling. If you are considering using pneumatic execution in your automated machines (such as connector assembly machines, it is essential to work with a reputable manufacturer who can help you design and build a system that meets your specific needs for automation production.