What types of testing and detection are essential during the assembly of a high current connector?

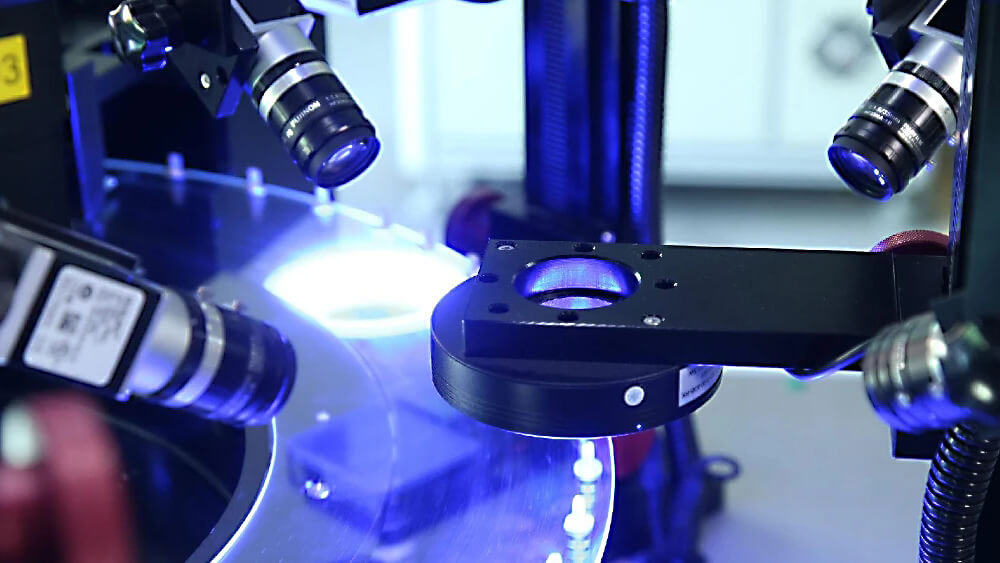

- Vision inspection

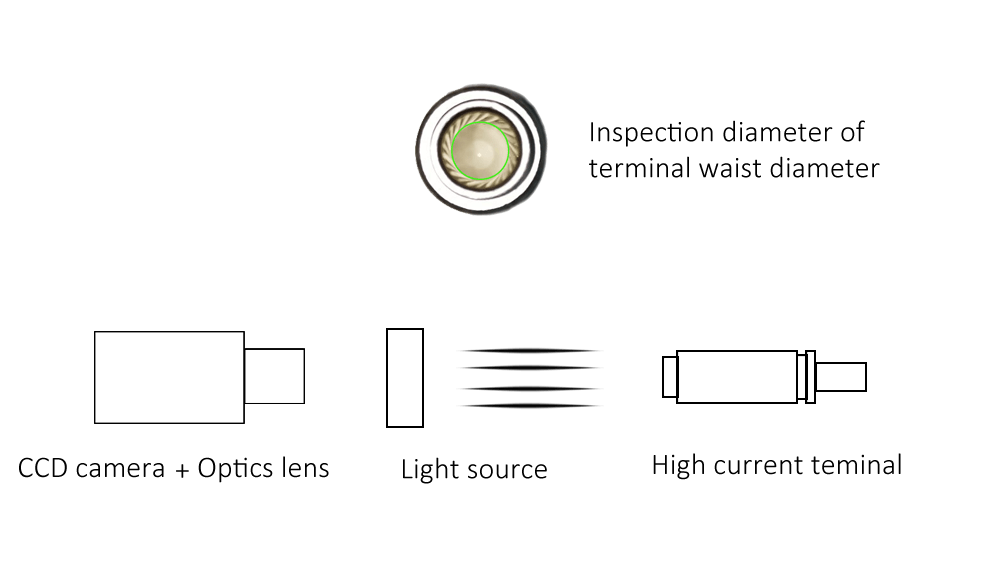

- CCD camera vision inspection—Precision Detection Technology for Xieli Automation Connector Machines

- CCD vision inspection—Multi-Point Defect Detection for High Current Connector Equipment

- Crack after swaging ring

- Damage of top profile

- Detecting half swaging retainer ring

- Retainer ring dislocation

- Spring damage or bend internal after test of load

- Profile of the swaging operation (oval shape)

- Residue and chipping in the internal hole

- Each checkpoint directly affects the performance of connectors, making CCD vision inspection an indispensable function of automated assembly machines.

- Male terminal and female terminal testing

- Insertion and withdrawal force test

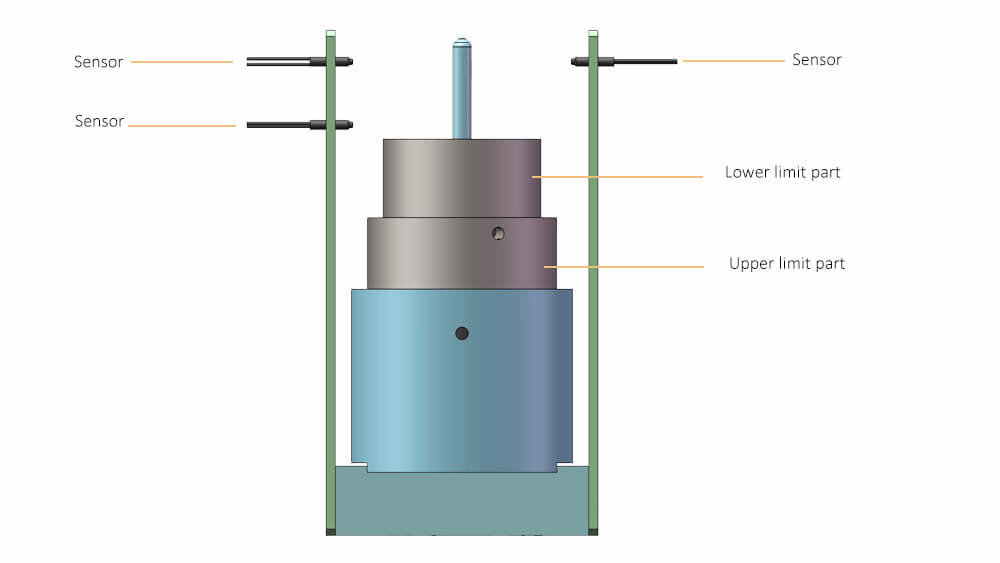

Mechanical test

Mechanical test is a traditional yet highly dependable method for assessing the insertion and withdrawal force of high current connectors. It requires specific parts weight and sensors—core components of the testing module in automated equipment—to detect whether the high current connector is qualified.

Case: Force=2N~6N

According to Newton’s Second Law F=ma “m” is part weight, a=g=9.8N/kg

Then Lower limit F1=2N=9.8N/kg x m1 Upper limit F2=6N=9.8N/kg x m2

m1=204g m2=612g

The parts weigh should be 204g and 612g.

Electrical test

Electrical test uses a resistance strain sensor—a type of force sensor that converts weight or pressure signals into electrical signals. It operates by using a metal resistance wire that elongates and thins when under tension, resulting in an increase in resistance—this high-precision test method is applied in Xieli Intelligent automated equipment to ensure connector electrical performance.

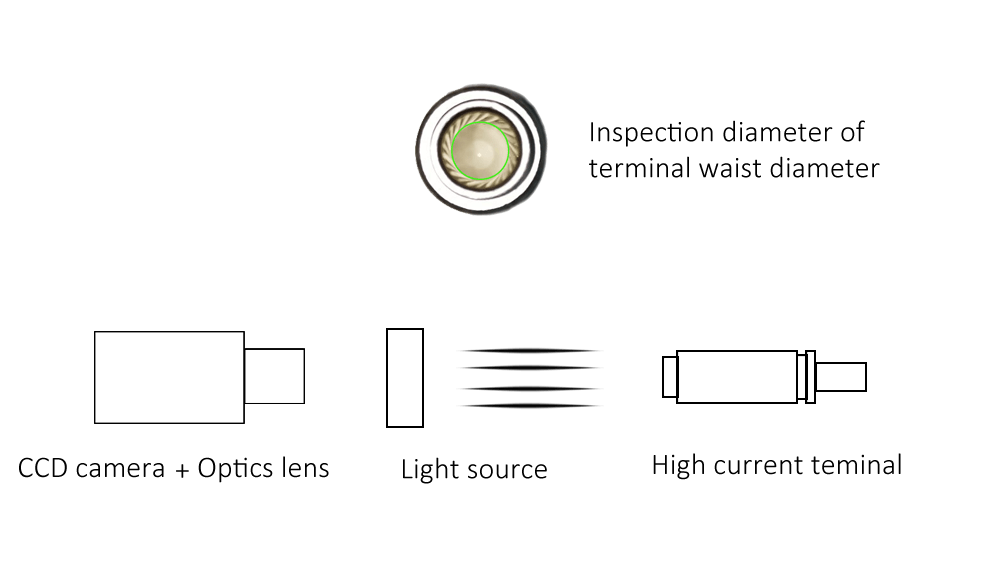

- In the automatic high current connector assembling machine, the CCD camera system is applied to detect the waist diameter (middle diameter) of springs, to ensure that each terminal is of high quality and every point of the middle of springs can make contact with male terminals. Accordingly, stable current flow between the female and male terminals is guaranteed.

- In addition to checking the waist diameter, the CCD vision inspection system is equipped to inspect multiple other checkpoints.

> Crack after swaging ring.

> Damage of top profile.

> Detecting half swaging retainer ring.

> Retainer ring dislocation.

> spring damage or bend internal after test of laod.

> profile of the swaging operation (oval shape).

> Residue and chipping in the internal hole.

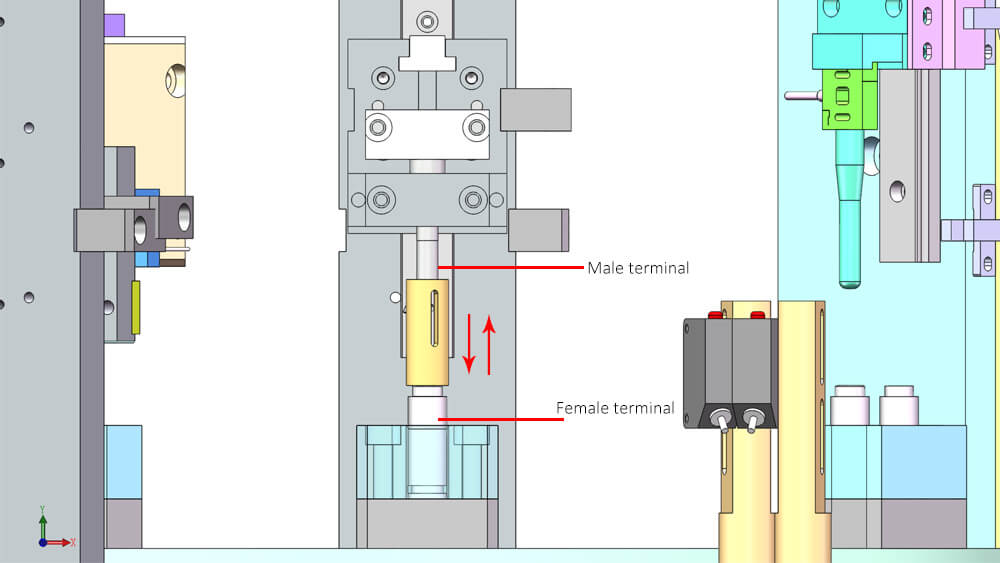

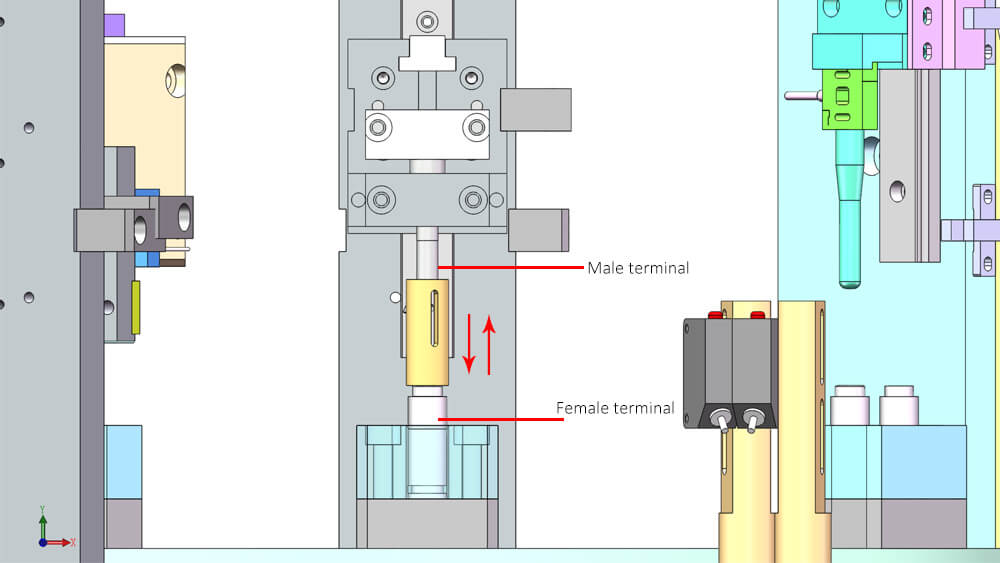

Male terminal and female terminal testing

Male terminal and female terminal testing play a crucial role in the operation of automated assembly machines. It is a vital workstation that ensures the quality and reliability of the final product.

The purpose of the male and female terminal testing is to eliminate the initial mechanical stress on the terminals. The mechanical stress will cause the spring to have uneven tolerance to external forces, which makes the insertion and removal process not smooth and the current is unstable.

Removing the mechanical stress can improve largerly the mechanical property of high current connector.

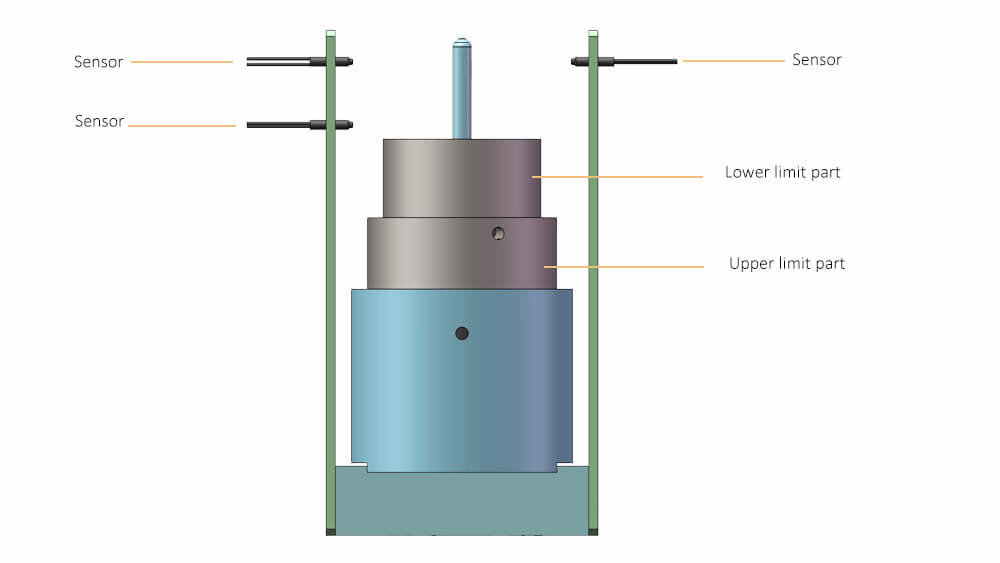

Insertion and withdrawal force test

Another essential test on automatic high-current connector machines is the insertion and withdrawal force test. The finished products wiil be screened out by an automation machine according to the design specifications or industry standards to determine if the component meets the required insertion or withdrawal force requirements.

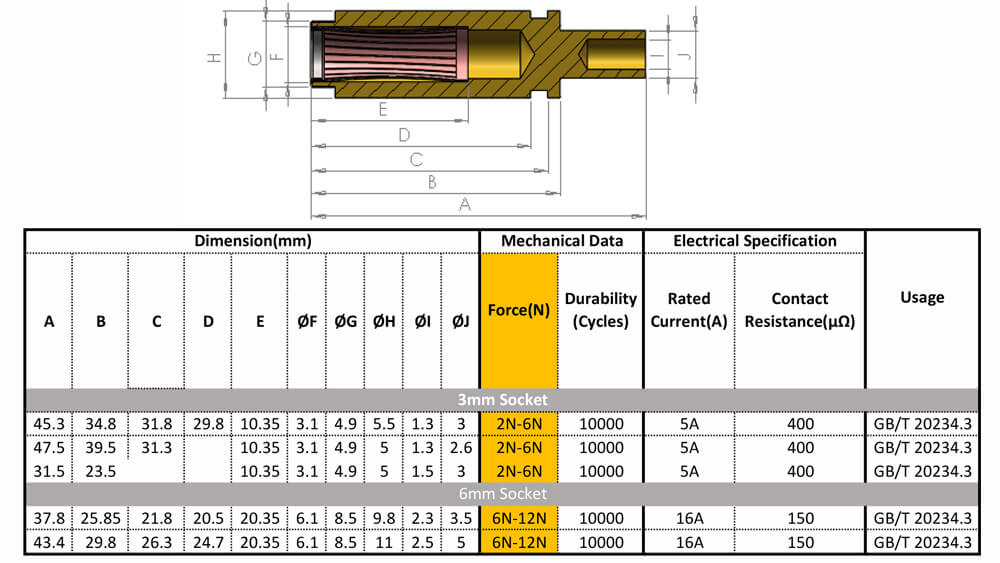

High current connector datasheet

There are two test methods on the automatic high current connector assembling machine. A mechanical test method and an electrical test method.

Mechanical test

Mechanical testing is a traditional yet highly dependable method for assessing the force required for insertion and withdrawal. It requires specific parts weight and sensors to detecting the high current connector qualification or not.

Case: Force=2N~6N

According to Newton’s Second Law F=ma “m” is part weight, a=g=9.8N/kg

Then Lower limit F1=2N=9.8N/kg x m1 Upper limit F2=6N=9.8N/kg x m2

m1=204g m2=612g

The parts weigh should be 204g and 612g.

Electrical test

It uses resistance strain sensor, is a type of force sensor that converts weight or pressure signals into electrical signals. It operates by using a metal resistance wire that elongates and thins when under tension, resulting in an increase in resistance.

Assembling a high-current terminal is a complex process that requires precision and attention to detail. In order to ensure that the terminal functions properly and safely, various types of testing and detection are necessary throughout the assembly process. Vision inspection, Male terminal and female terminal testing, Insertion and withdrawal force test are all essential types of testing.

Certainly, there is not only the above test function can be installed on automatic high current connector assembling machine. The machine is customized according to physical products standards and requirements, such as resistance testing. Therefore, it is an important to clarify the details and request nt of the high current connector before producing.