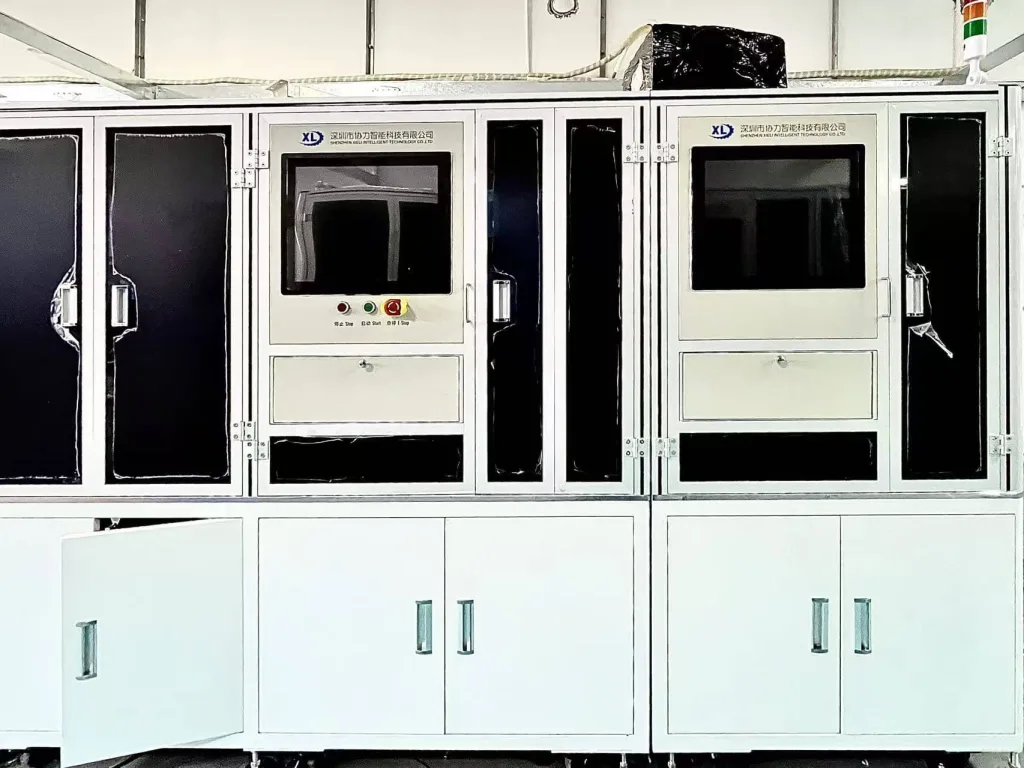

Automatic PV Connector Assembly Machine

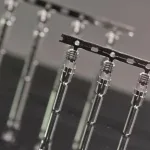

High-precision vision guidance (e.g., CCD positioning) is adopted to solve the alignment problem of micro-components; the vision system identifies scratches, material shortages and stains, and defective products are automatically rejected by an air-blowing device.

| Cycle period | 1.5 S/PCS (2 out of 1 mode) |

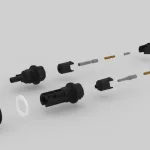

| Number of assmbled materials | 3 |

| Equipment utilization rate | 85% |

| First pass yield | 99.50% |

| Required operators | 0.5 |

| Dimensions | L4500mm*W800mm*H1900mm |

| Power | 2KW/H |

| Operating air pressure | 0.5-0.7MPa |

- MC4 Series Automated Mass Production

- The equipment supports quick mold changeover, enabling it to adapt to the production of connectors of different specifications (such as MC4, H4, etc.).

- The vision system identifies scratches, material shortages, and stains, and defective products are automatically rejected by the air-blowing device.

- Process Content:

- Metal wires (copper/tinned copper) and plastic pellets (nylon, PBT, etc.) are automatically fed via vibratory feeders and conveyors.

- A vision system is used to identify the orientation of materials, and a deviation correction device ensures precise positioning, avoiding errors caused by manual intervention; meanwhile, it is equipped with an automatic insertion and extraction force testing device.

- Core Steps:

- Terminal Insertion: A robotic arm accurately inserts metal terminals into plastic housings, and force feedback ensures that the insertion is in place.

- Locking Mechanism Installation: Accessories such as springs and buckles are supplied by vibratory feeders, and the assembly is completed by robots.

- Difficulty Breakthrough: High-precision vision guidance (e.g., CCD positioning) is adopted to solve the alignment problem of micro-components; the vision system identifies scratches, material shortages, and stains, and defective products are automatically rejected by the air-blowing device.

- Equipment installation and commissioning: Provide professional technicians for on-site installation and commissioning to ensure normal operation.

- Training service: Provide comprehensive technical training for customer operators and maintenance personnel to ensure proficient operation.

- Warranty service: 1-year warranty for the whole machine, 2-year warranty for core components, and lifetime technical support.

- Maintenance service: Response within 2 hours after receiving fault notification, and arrange technicians to arrive within 48 hours (domestic).

- Parts supply: Long-term supply of original genuine parts to ensure continuous and stable operation of the equipment.

Contact Us

FIll out the form below and we will cantact you as soon as possible

industries

Quick Links

Get In Touch

Room 301, Building 1, No. 44, Dongfeng Road, Songgang Community, Songgang Street, Bao’an District, Shenzhen City

- Email:aven @connauto.com

- Phone: +86 15170096867